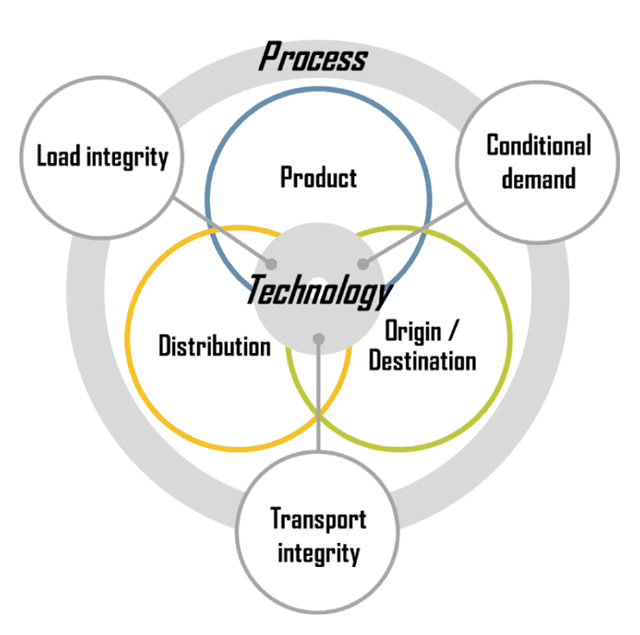

Elements of the Cold Chain

A cold chain can functionally be considered as the close interaction between three technologies:

- Product-

A product has physical attributes requiring specific temperature and humidity conditions. These conditions dictate its transport, which must takes place in a manner that does not undermine its physical attributes to an extent that is judged unacceptable. These physical attributes relate to how perishable and fragile a product can be; how it handles the cold chain process. Otherwise, the product may lose its commercial value in whole or in part.

- Origin / Destination-

The respective locations of where a temperature-sensitive product is produced and consumed. It underlines the difficulty of making a product available at a market from where it is produced, which can be an important constraint. Because of advances in cold chain logistics, it became possible to use increasingly distant sourcing strategies, some of which are spanning the world.

- Distribution-

The methods and infrastructure available to transport a product in a temperature-controlled environment. They can involve temperature controlled containers (reefers), trucks and warehousing facilities.

The major cold chain technologies in providing a temperature controlled environment during transport involve:

- Dry ice-

Solid carbon dioxide, is about -80°C and is capable of keeping a shipment frozen for an extended period of time. It is particularly used for the shipping of pharmaceuticals, dangerous goods and foodstuffs and in refrigerated unit load devices for air cargo. Dry ice does not melt, instead it sublimates when it comes in contact with air.

- Gel packs-

Large shares of pharmaceutical and medicinal shipments are classified as chilled products, which means they must be stored in a temperature range between 2 and 8°C. The common method to provide this temperature is to use gel packs, or packages that contain phase changing substances that can go from solid to liquid and vice versa to control an environment. Depending on the shipping requirements, these packs can either start off in a frozen or refrigerated state. Along the transit process they melt to liquids, while at the same time capturing escaping energy and maintaining an internal temperature.

- Eutectic plates-

Also known as "cold plates". The principle is similar to gel packs. Instead, plates are filled with a liquid and can be reused many times. Eutectic plates have a wide range of applications, such as maintaining cold temperature for rolling refrigerated units. They can also be used in delivery vehicles to keep temperature constant for short periods of time, a process that can be suitable for deliveries in noise sensitive areas or for night deliveries.

- Liquid nitrogen-

An especially cold substance, of about -196°C, used to keep packages frozen over a long period of time. Mainly used to transport biological cargo such as tissues and organs. It is considered as a hazardous substance for the purpose of transportation.

- Quilts-

Insulated pieces that are placed over or around freight to act as buffer in temperature variations and to maintain the temperature relatively constant. Thus, frozen freight will remain frozen for a longer time period, often long enough not to justify the usage of more expensive refrigeration devices. Quilts can also be used to keep temperature sensitive freight at room temperature while outside conditions can substantially vary (e.g. during the summer or the winter).

- Reefers-

Generic name for a temperature controlled transport unit, which can be a van, small truck, a semi-trailer or a standard ISO container. These units, which are insulated, are specially designed to allow temperature controlled air circulation maintained by an attached and independent refrigeration plant. A reefer is therefore able to keep the cargo temperature cool and even warm. The term reefer increasingly apply to refrigerated forty foot ISO containers.